In the mall, there are many shops, they have all kinds of display props. These props are also made of different materials, and different metals are given different finishes. It also makes the display items reflect different effects. If you want your product to look good you have to choose the right treatment, Our factory can finish electroplating at Powder coating. Metal drawing, sandblasting and other metal surface treatment. If you need to manufacture metal display props, please contact us as soon as possible. I will introduce these processes in detail.

Powder spraying

Is a powder spraying equipment (electrostatic spraying machine) to spray the powder coating to the surface of the workpiece, under the electrostatic action, the powder will be evenly adsorbed on the surface of the workpiece, forming a powdery coating; The powder coating is cured by high temperature baking and leveling to become the final coating with different effects (different kinds of effects of powder coatings).

Rich color, highlight, matte optional; Low cost, suitable for building furniture products and chassis shell, etc., strong ability to cover defects.

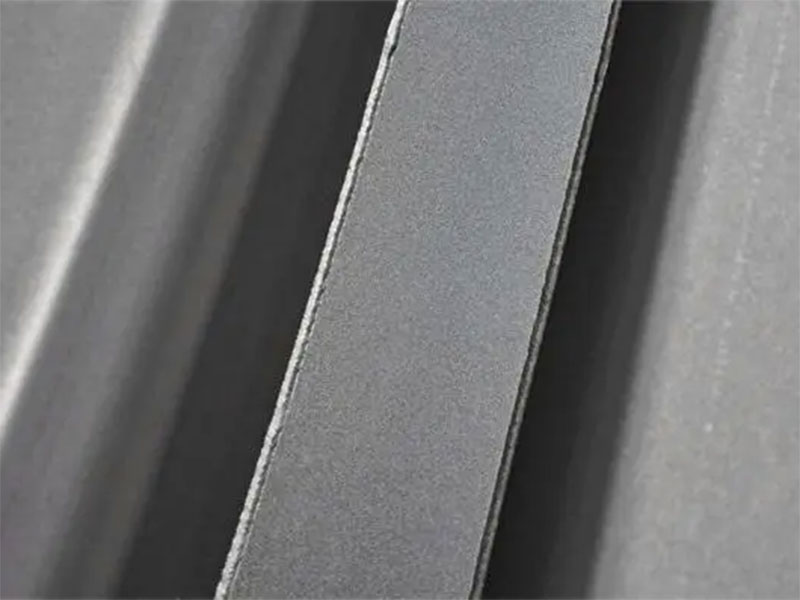

Metal drawing

It is a kind of surface treatment means of decorative effect by grinding products to form lines on the surface of the workpiece. According to the different lines after drawing, it can be divided into straight lines, random lines, corrugations and spiral lines.

Advantages: The drawing treatment can make the metal surface obtain non-mirror like metallic luster, and the drawing treatment can also eliminate the subtle defects of the metal surface.

Sandblasting

The compressed air is used as the power to form a high-speed jet beam to spray the material at high speed to the surface of the workpiece to be processed, so that the appearance or shape of the outer surface of the workpiece surface changes, to obtain a certain degree of cleanliness and different roughness of a process.

Advantages: Achieve different reflective or matte light. Can clean the small burr on the workpiece surface, and make the workpiece surface more smooth.

Polishing

The modification of the workpiece surface by means of flexible polishing tools and abrasive particles or other polishing media.

Advantages: Does not change any physical properties of the material, can do other surface pretreatment process.

So let me show you some pictures of the products of these processes

After reading the treatment methods of these metal surfaces, I hope you can have a better understanding of which treatment method is needed for your products. If you want to mass manufacture display props, please contact us. Our factory covers an area of 20,000㎡. Bulk production lead time is 25~35days. We obtain satisfaction of customers with high quality products. We're committed to becoming the preferred partner of world's leading brands, offering better service and moving towards a better future. We provide you display props made of metal, wood, acrylic etc. We own a professional export team, offering full services. We're trusted by our customers with high efficiency, high quality manufacturing and export services.

Post time: Oct-21-2022